Custom-Designed Image Sensor: Development Insights from the BergKristall Project

Designed by our R&D team to meet demanding requirements in high-speed industrial imaging, the Tichawa Vision BergKristall sensor was developed as a flexible and scalable platform. We spoke with the ISDI Senior Design Engineer behind the project to learn more about the development process, the key challenges, and how collaboration shaped the outcome.

BergKristall Sensor

Engineering Precision: Key Features of the BergKristall Sensor

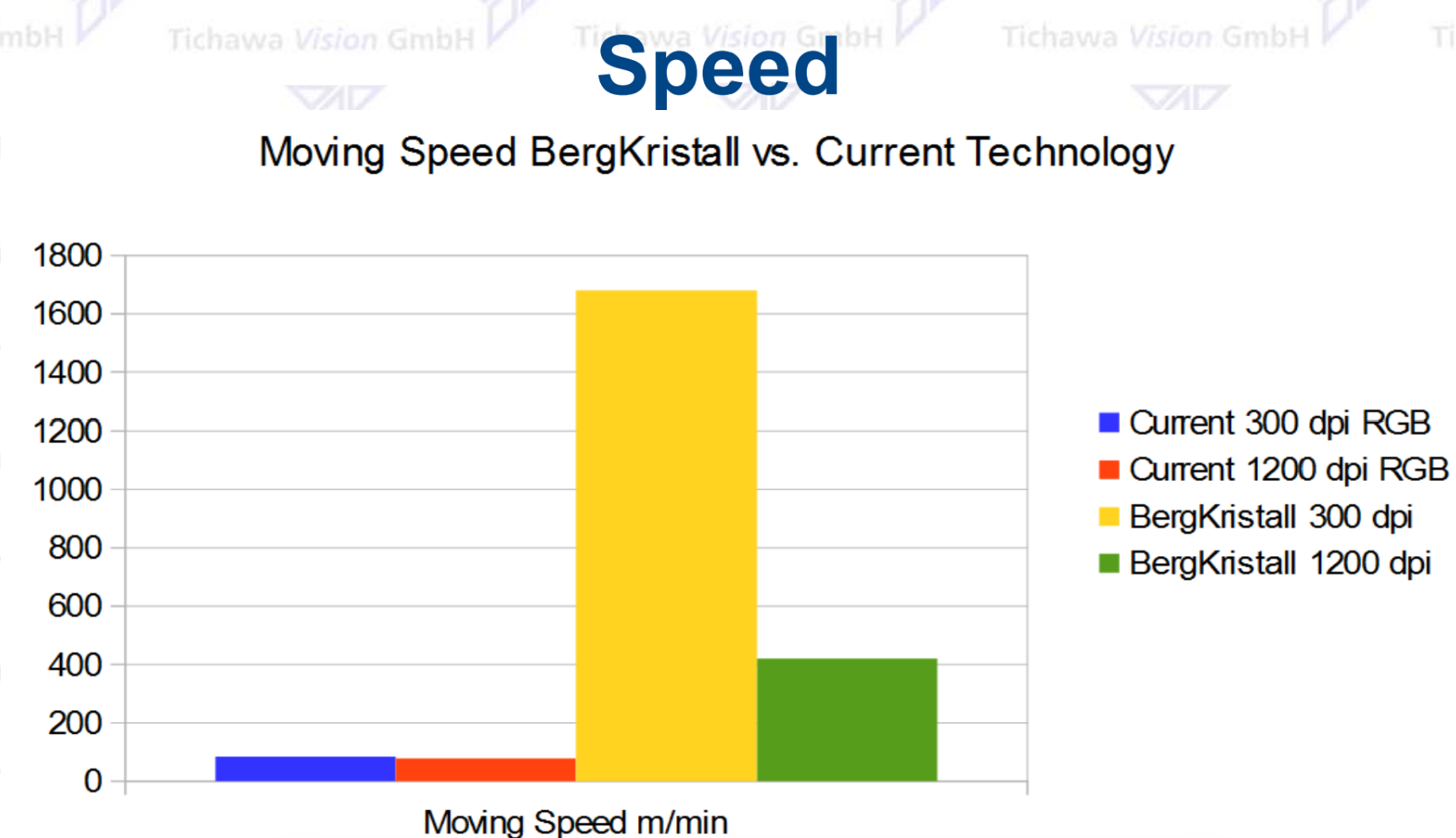

The BergKristall Sensor features Zero Gap Sensor technology for seamless imaging, and supports over 25 illumination geometries - including darkfield, brightfield, transmission, and multispectral - in a single platform. It achieves line rates of up to 1 MHz via ROI (Region of Interest) mode, and offers image resolutions of up to 4800 dpi through specialized optics. A 12-inch wafer can be scanned in as little as three seconds. With support for 8- to 14-bit grayscale, the sensor is suited for applications requiring fine contrast resolution, such as material density measurements in paper, print, and coatings.

Tackling Technical Challenges

From the beginning, the project required several custom solutions. “The high-speed readout requirement, combined with the tight pixel pitch, forced us to rethink our approach to converter architecture,” the engineer recalls. “We decided to develop a custom single-slope ADC, which gave us the right balance between speed and area efficiency.”

Another significant challenge was the requirement for random row access - something not previously implemented in this sensor line. “This meant we had to build the entire readout timing around that constraint,” he explains. “It also required us to develop high-speed interface logic for both addressing the array and connecting to the FPGA.”

The complexity increased with the decision to integrate multiple pixel densities into the sensor. “One of those had an exceptionally small pitch, and we didn’t have a proven in-pixel layout for that. We had to develop an entirely new ultra-compact design to fit all the required electronics.”

A Structured Approach to Sensor Design

Unlike previous ISDI sensor developments, this project demanded a detailed, timing-driven design methodology. “Because we needed to support both analog and digital CDS modes, as well as non-CDS readout, we had to carefully plan every stage of the signal chain - from pixel sampling to data conversion and transfer,” the engineer notes. “This required defining and validating the timing structure before we even started the actual design.”

Two technical firsts were introduced with BergKristall: random row addressing, which was completely new to our product line as we had previously only worked with progressive scan models, and serial readout multiplexing, which allows the sensor to operate in more power-efficient modes at lower speeds and ultimately proved to be a valuable addition.

Project Collaboration and Development Process

Beyond technical hurdles, the collaborative development process was a central factor in the project’s success. “From specification through to testing, we worked closely with the customer. It really felt like a joint development effort,” the engineer reflects. “During the testing phase especially, their feedback helped us implement very detailed verification and production testing routines.”

A Flexible Sensor Platform

With the sensor now in use, the team sees the outcome not just as a finished product, but as a flexible platform. “The architecture is already being adapted for different applications,” says the engineer. “We were able to fulfil the original requirements, and I think the project laid the groundwork for future developments.”

Video Interview with Nikolaus Tichawa

To find out more about ISDI’s custom design project for Tichawa Vision GmbH take a look at this video interview with Andrea Baum ( ISDI ) and Nikolaus Tichawa ( Tichawa Vision GmbH ) about the BergKristall sensor.

Conclusion

The BergKristall sensor was developed to meet specific technical requirements through a structured and collaborative process. With its support for various illumination modes, high-speed readout, and flexible integration options, it provides a configurable imaging solution for demanding applications - ranging from wafer inspection to density measurement and beyond.